I. Industry background

(I) From "plant protection drones" to "agricultural drones"

As early as 1987, Japan developed the world’s first plant protection drone, selling them in limited quantities the following year. Of the nearly 5 million hectares of arable land in Japan today, over 20% uses plant protection drones to control pests and weeds. Drones have become an important plant protection technology measure in Japan.

China’s plant protection drones began to develop in 2007, and in 2010, the 3CD-10 single-rotor gasoline-powered plant protection drone produced by Wuxi Hanhe Aviation was exhibited for the first time at the National Agricultural Machinery Expo. This was the first drone of its kind sold in China, opening the first step of commercializing plant protection drones in the country.

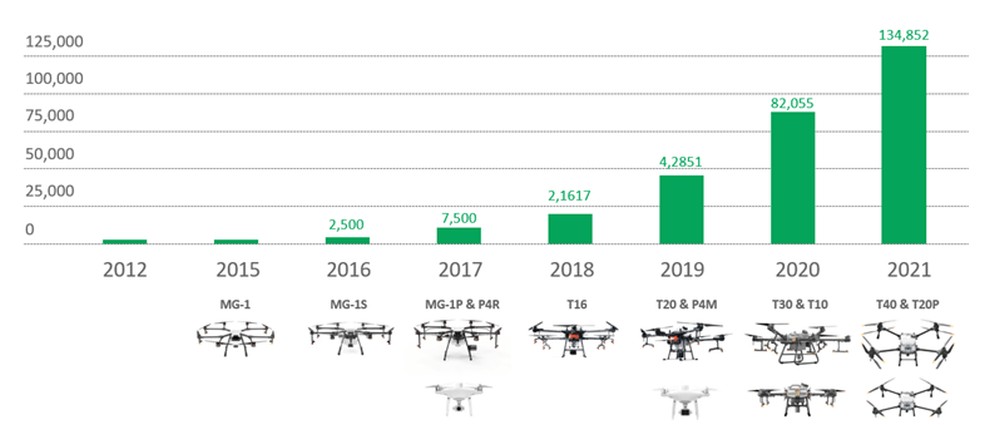

In 2012, DJI applied the world’s superior drone technology to agriculture and founded DJI Agriculture in 2015 with the release of the MG-. In 2015, XAG released its plant protection drones and established XAG Agricultural Services. Today, several drone companies are dedicated to providing users with agricultural solutions based on drone technology to drive innovation and progress in global agriculture.

With the rapid development of plant protection drones, smarter products have been created to serve a wider range of needs and applications. In addition to spraying pesticides, plant protection can also spread fertilizer, seeds, and feed. As a result, the term “plant protection drone” is gradually being replaced by the broader term “agricultural drone.”

2021 was a year of rapid development of agricultural drones worldwide, which is a quantitative leap compared to 2020 in terms of the total number of drones and operating areas. Drones are particularly suitable for scenarios where it is difficult to get down to the ground with manual and ground machinery, such as paddy fields, tall straw crops, and mountainous terrain. In Southeast Asia, where rice is a staple crop, drones are gaining recognition from more and more farmers. Operations have grown rapidly, as agricultural drones are suitable for sowing rice fields and controlling pests throughout the crop growth cycle. The application of agricultural drones in flat farmland such as wheat and rice is quickly gaining popularity, and with the continuous improvement of technology, the application has been expanded in complex scenarios such as hilly mountain orchards.

In Europe, many vineyards have steep mountainous terrain where ground machinery is not available, so most work is done by hand, with high labor and time costs. In Hallau, in the canton of Schaffhausen in northern Switzerland, the preservation of traditional farming practices also poses a challenge for efficient management of local vineyards. To ensure yields, vineyard managers spray pesticides every season. Previously, this work was mainly done manually by hired workers in an inefficient, physically demanding process. The growing season typically required 8-10 sprays, each of which took more than 10 days, and if not sprayed in a timely manner, grape mold could affect a season’s wine production and harvest, but also vineyard income for years to come.

Hallau is located in the mountainous northern region, whose terrain was challenging for ground-based vehicles. On some steep slopes, a vehicle can easily tip over, threatening the driver’s safety. The invocation of drone management to maintain the original ecology of the vineyard to the maximum extent is a new attempt to integrate the traditional culture of the local vineyard with modern technology. This was also the first time that Chinese intelligent agricultural equipment entered the local agricultural production in Switzerland.

(II) Key concerns for industry development

1. Regulation and policy

Agricultural drones, as the name implies, are drones used in agriculture. Their purpose places them in the category of agricultural equipment, which is managed by the agricultural department; when it sprays pesticides, it has potential environmental risks, which are managed by the environmental protection department. At the same time, their operational attributes belong to the aircraft category and is managed by the civil aviation authority. This characteristic of agricultural drones, which is managed by multiple authorities, leads to the fact that laws and policies play an important role in the development of the industry.

The management of agricultural drones as agricultural equipment is a common method all over the world, while each country’s management methods differ by some degree. Some countries adopt compulsory certification, some apply for simple written materials, while others use administrative authorization. Nevertheless, it represents the Ministry of Agriculture’s management and approval of agricultural drones.

As a kind of aircraft, an agricultural drone is managed by civil aviation authorities of various countries in its operation. There are three common ways of management. The first is to exempt agricultural drones with low-risk operations in the existing legal system, such as the United States. The second is to require drones above 25 kg to carry out a Safe Operation Risk Analysis (SORA). This assessment focuses on operational risk and analyzes and approves the operational risk of individual cases, which is widely used in European countries. The third is to simplify the airworthiness rules of traditional aircraft and generate a simplified version of airworthiness requirements that apply to agricultural drones, such as Brazil, Mexico, and other countries.

Agricultural drones are mainly used for pesticide spraying, so the management of pesticides has become the third policy direction to pay attention to. In Japan, for example, the management agency of pesticide preparations for drones is the Agriculture, Forestry and Fisheries Aviation Association. Japan has 382 pesticide formulation registered for agricultural drones.[1]

Pesticides registered in Japan for agricultural drones include fungicides, insecticide mixtures, herbicides, and plant growth regulators, and registered crops are mainly rice, wheat, soybeans and so on. Herbicides are only registered in rice fields, and the pesticide forms registered in rice fields are mainly granules and film oil. The application method is to use drones to spread particles and drop film oil.

On the premise that the registration of conventional spray use on the ground has been obtained, pesticide companies can apply for the expansion test of low-volume spray use of agricultural drones to increase the registered mode of application. The registration test of Japanese flight control medicament includes tests for field efficacy, residue, crop safety, and adjacent crops. The registration of trials is mainly carried out by the Japan Agricultural Aviation Association (JAAA).

In February 2019, the Ministry of Agriculture, Forestry, and Fisheries of Japan simplified the efficacy and residue tests of special agents for agricultural drones based on years of experience in the use of drones. However, crop safety and drift tests related to drone spray are still important registration test data to be submitted. Registration of crop safety tests generally requires “two places a year” – that is, tests are carried out in two fields within one year, and the test dose is twice the recommended dose. Crop safety tests can be carried out at the same time as efficacy tests. For the safety test of adjacent crops, it is necessary to select five sensitive crops to carry out the tests.

2. Efficiency needs to be balanced with environmental protection

Agricultural drone companies have made it their duty to improve agricultural efficiency, committed to improving global agricultural production efficiency. But human health is closely linked to the health and biodiversity of the world as a whole. With the continuous upgrading of the hardware system and intelligence of agricultural drones, only “improving global agricultural production efficiency” can no longer adapt to the development of the current moment, and environment-friendly agricultural drones will become the direction of the industry.

As traditional aerial spraying drift has had a negative impact on the environment, the European Union issued the Directive on the Establishment of a Community Framework for Action to achieve the Sustainable use of pesticides (DIRECTIVE 2009/128/EC, hereinafter referred to as “the Directive”) in 2009, which completely banned aerial spraying in principle and allowed spraying only on steep terrain that could not be reached by ground equipment and when aerial spraying had obvious advantages over ground equipment. Over the past decade, the Directive has been widely transformed into domestic law in EU countries, and has formed a complementary management system with other environmental and agricultural regulations in various countries. For example, Italy has to apply for an overall environmental assessment of the spraying plan before aviation spraying, and then apply for approval in accordance with civil aviation regulations.

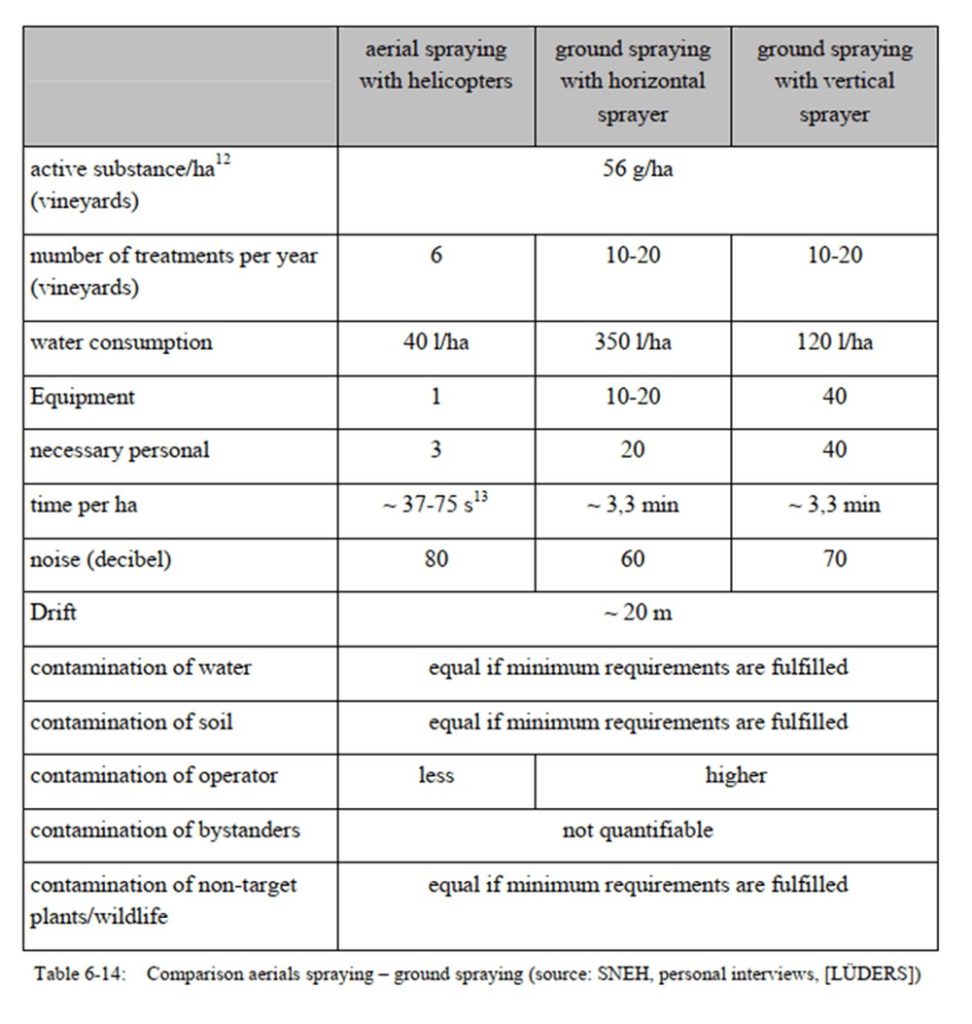

Prior to the formal release of the Directive, the EU solicited comments from social groups and stakeholders on the draft legislation on a large scale. The legislature entrusts Bipro[2] to carry out corresponding tests to ensure the scientific and social basis of legislation. According to Bipro’s report “Assessing economic impacts of the specific measures to be part of the Thematic Strategy on the Sustainable Use of Pesticides,” the EU selected three traditional agricultural countries – France, Spain and Germany – to conduct comparative tests of aerial spraying and ground spraying, respectively, for grapes (France), olives (Spain) and forests (Germany). Considering many factors, such as economic benefit, social impact, environmental impact, spraying efficacy, and human health, the tests compared ground agricultural equipment spraying with aircraft spraying.

As shown in figure 5, taking the test in the French vineyard as an example, it can be seen that the drift distance of aerial spraying and artificial spraying in the vineyard is about 20 meters.

In 2019, the European Union issued an amendment to the Directive. However, there is no change in the basic position of the directive on aerial spraying: prohibition in principle and exemption in special circumstances. In the thirteen years since the formation of the Directive, civil agricultural drones have still not yet been widely used. With the development of science and technology, agricultural drones can replace human beings in more situations. Therefore, it is time to reassess the legitimacy of agricultural drone operations rather than managing them as traditional aircraft.

II. Advantages of agricultural drones compared with aircraft spraying

Compared with traditional aircraft, the characteristics of spraying by agricultural drone are mainly concentrated in the following aspects:

(I) Environmentally friendly

1. Precision spraying operation

The small fixed wings and small helicopters used in agriculture have high flight speed and high flight altitude during spraying, which may lead to serious spray drift. The drone can hover for more targeted high-precision spraying, with lower operating altitude (usually 1.5-3.5m above the crop surface), slower flight speed (about 3-7m/s), and more dynamic control of sprinkler and flow velocity to prevent drift.

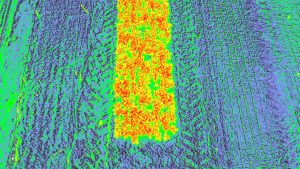

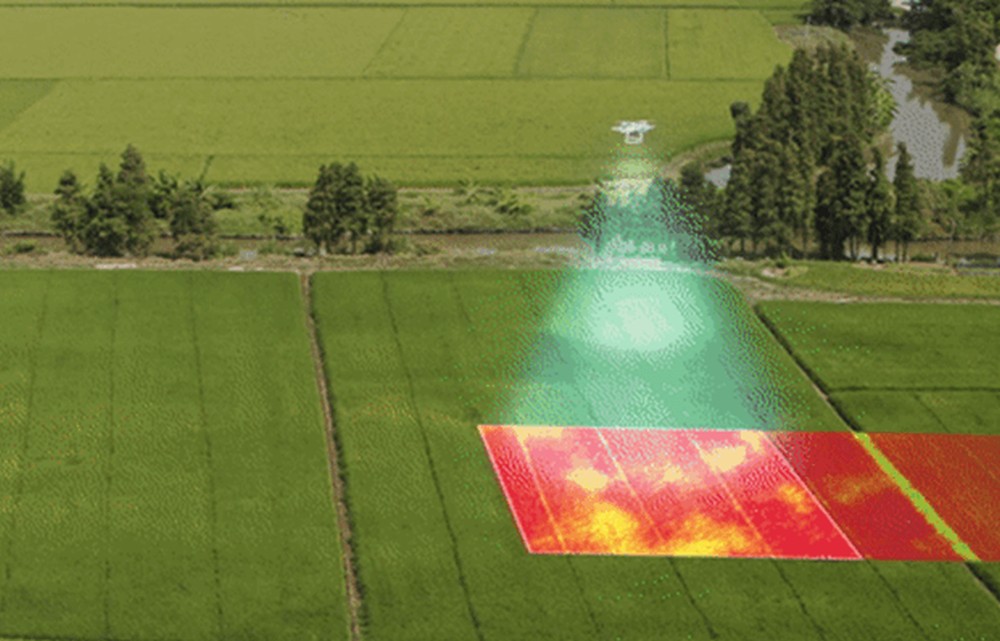

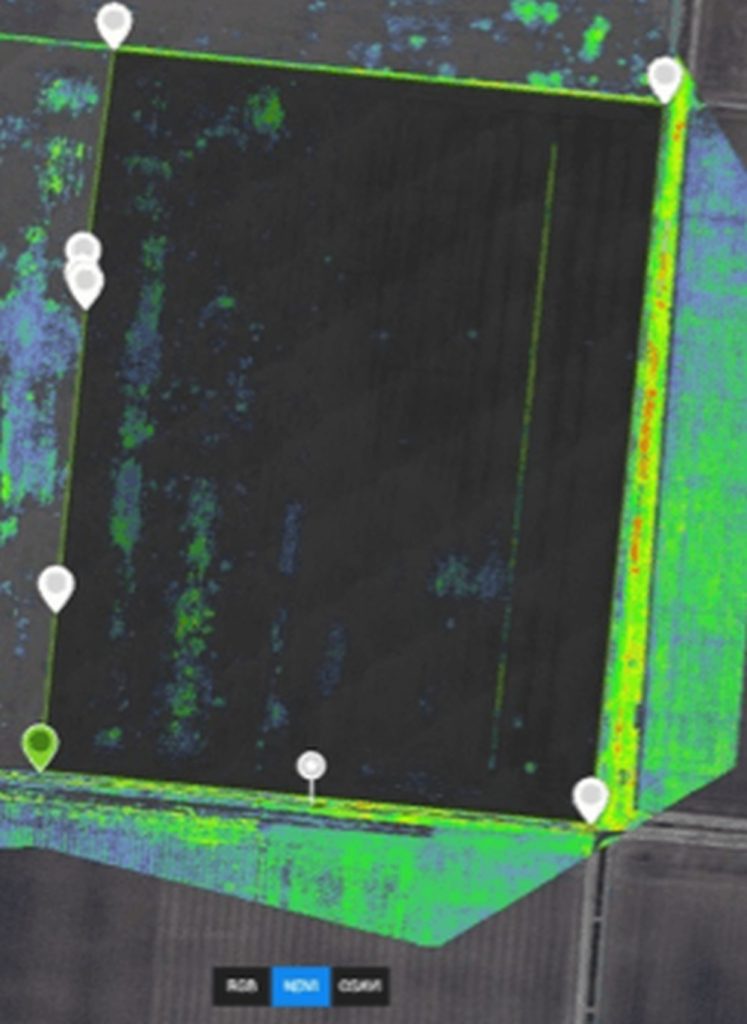

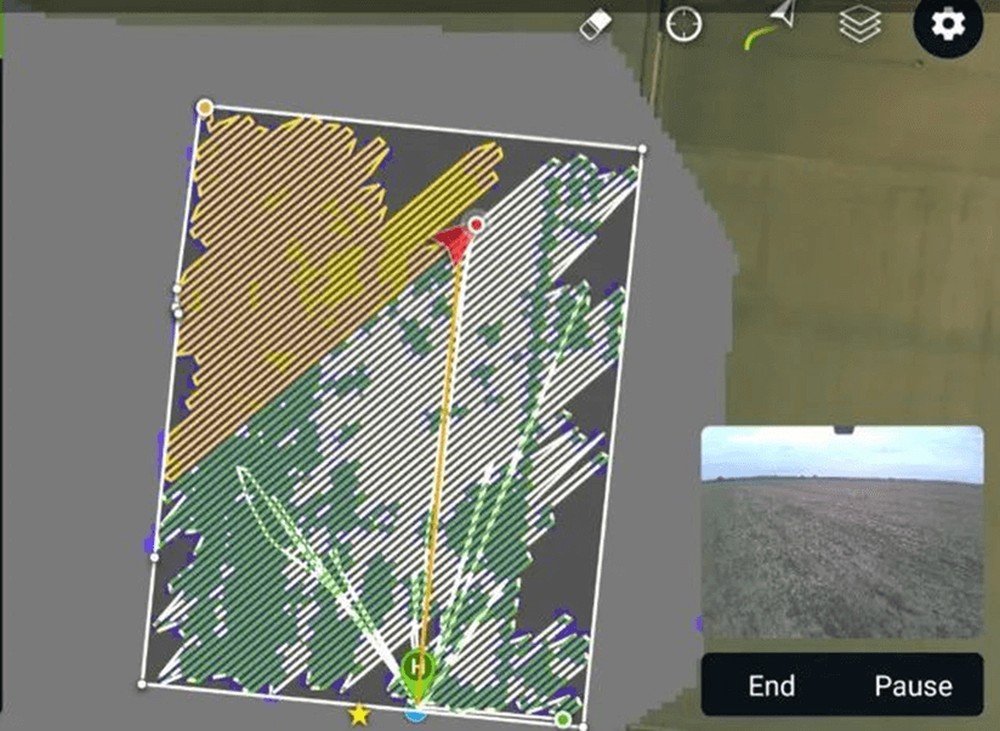

Mounting multi-spectral lens on drone can realize the collection and supervision of farmland operation information, generate agricultural prescription map according to the growth of crops, and guide the operation of agricultural drone. When spraying pesticides by drone, it only aims at the plots that need to be sprayed, so as to further reduce the impact on the environment.

In terms of precision spraying, the agricultural drone has garnered attention in addressing the spread of Cirsium arvense in recent years. Cirsium arvense, also known as creeping thistle, is a malignant weed, widely distributed in farmland and pasture, competing with crops for water, nutrients and minerals. Its root buds produce acids that make the soil unsuitable for the growth of some crops. As a result, crop yields are reduced, causing economic losses to farmers and farm owners.

The root buds of Cirsium arvense can continue to reproduce even if it is damaged, so the general process of soil preparation (e.g., cultivated land, ploughing) cannot remove Cirsium arvense, and will further help it spread and propagate. Therefore, the only effective treatment is internal inhaling herbicides, which is conventionally done by spraying glyphosate on the whole field with a tractor.

Planta Drone[3], a partner of DJI Agriculture in Hungary, once used multi-spectral drones to monitor the distribution of Cirsium arvense in the fields, and then used agricultural drones for precision spraying, in order to reduce pesticide use and cost. Planta Drone used multispectral drones to monitor the fields before and after sowing, and then separated the growth of Cirsium arvense using NDVI vegetation index. After the prescription map of precision spraying was generated, the agricultural drone could spray according to the prescription map, so as to achieve accurate weeding.

2. Reduce the risk of operators

The typical agricultural operation scenarios of helicopters and fixed-wing aircraft are in mountain terrain operations and large-scale farmland operations. Mountain operation requires pilots to fly manually and constantly ascend and descend to ensure effective spraying. In large-scale farmland operation, the aircraft needs to work at an altitude close to 5 m of the crop. In this process, many pilots cannot successfully level the aircraft after flying close to the ground, increasing the likelihood of a crash. A study from the United States National Transportation Safety Board found that in 2013 there were 78 agricultural aircraft accidents, of which nine were fatal, claiming the lives of 10 people.[4]

The spraying operation of drone first solves the traditional method of “human-aircraft binding,” where pilots must be onboard the aircraft. In the new “human-aircraft separation” method, the drone pilot does not have to bear the risk of crashing. The automatic operation mode of the drone also does not require the pilot to constantly follow the drone, which avoids the risk of the pilot contacting the pesticides during the agricultural spraying operation.

The agricultural drone is equipped with a spherical radar system composed of omnidirectional obstacle avoidance radar and upward radar, which can provide altimetry and height determination functions in front, rear and lower directions under different operation modes, in order to achieve terrain following function, horizontal omnidirectional obstacle avoidance, and upward obstacle avoidance function. Agricultural drones support terrain slope detection, and mountain slopes can also follow the terrain. In the course of route operation, it also has the function of horizontal omnidirectional obstacle bypass, and the obstacle avoidance path can be planned to bypass the obstacle independently.

3. Decreased environmental pollution

Traditional aircraft generally a fuel power source, while drones use lithium batteries. Electric energy is cleaner and can effectively save energy and reduce emissions.

Helicopter propellers produce sound as high as 110 decibels, 1.5 times what the human body can tolerate, while drone operations reduce noise decibels. When the drone works away from the crowd and operators, its low noise will not cause damage to the human body.

(II) Cost effectiveness

The purchase and maintenance costs of a traditional aircraft is high. The purchase cost of an aircraft is not only hundreds or even thousands of times that of drones, as well as more expensive to use. The aircraft requires a number of crew members to be on standby on the ground to do a series of maintenance before takeoff. At the same time, due to the need to apply for specific operational airspace, the cost of aircraft transfer is also relatively high in some countries and regions.

Take the global best-selling helicopter Single Squirrel AS350 as an example. The price of the model is about 3.6 million euros, the charge capacity is 600 kg, the length of the spray rod is 10 meters, the operating parameters are about 40 m/s, the height is 30 m, the spray amplitude is 50 m, the working efficiency is 1200 mu / mission, and each sortie takes 25 minutes. The aircraft is flown by two pilots and at least four ground crew members are responsible for ground maintenance.

By contrast, the cost of purchasing drones is relatively low, with a price of no more than 25,000 euros for an agricultural drone, which farmers can afford. Purchasing the professional plant protection services provided by the plant protection team will not cause a great economic burden. The repair and maintenance of agricultural drones are relatively simple, the replacement of high-consumption parts such as blades can be completed by the operator, and more complex repairs are usually done at the agent maintenance points near the operation area. The maintenance of drones can be done simply at the end of each operation, or uniformly at the end of the entire operation season.

|

|

Single Squirrel AS350 |

DJI Agras T30 |

|

Cost |

3.6 million euros |

No more than 25,000 euros |

|

Ground crew needed |

4 |

0 |

|

Pilots needed |

2 |

1 |

|

Energy |

Fuel |

Lithium battery |

|

Load |

500-600 kg |

30 kg (spray) |

|

Speed |

30-44 m/s |

3-7 m/s |

|

Spray amplitude |

25-50 m |

5-8 m |

|

Precision spraying |

No |

Yes |

Table 1: Helicopter vs. agriculture drone

III. Comparative advantages of drone and ground machine

1. Reduce carbon emissions

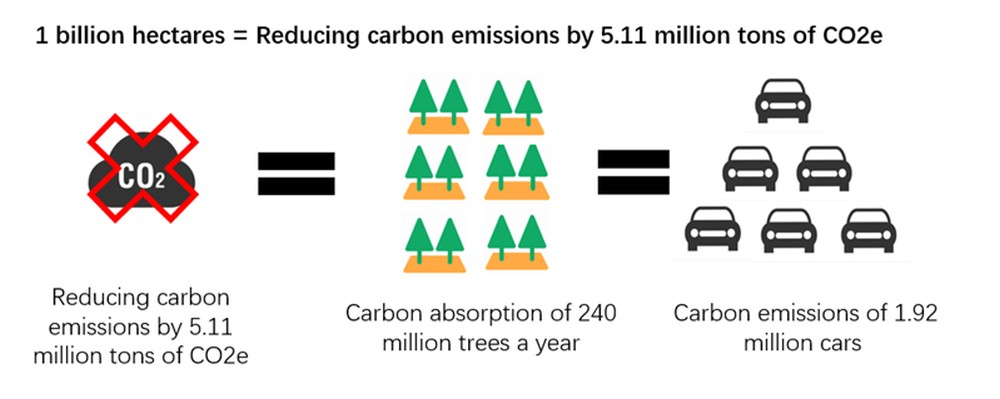

Spraying pesticides and fertilizers on farmland used to be dominated by human operations or tractor operations. Diesel is the main fuel for traditional tractors. Replacing traditional agricultural machinery with drones for plant protection can reduce carbon emissions to 5.11 kg of CO2 per hectare. The operation of 1 billion hectares is equivalent to reducing carbon emissions by 5.11 million tons of CO2. This is equivalent to the carbon absorption of 240 million trees a year, and the equivalent of reducing the carbon emissions of 1.92 million cars.

2. Reduce water consumption

Due to the use of low-capacity spraying technology, agricultural drones can save 44 litres of agricultural water per hectare compared with manual operation. The operation of 1 billion hectares is equivalent to a reduction of 44 million tons of agricultural water. This is equivalent to the amount of water consumed by 79.87 million residents in a year.

3. Improve the utilization rate of pesticides

The application of agricultural drones has also brought about an improvement in the utilization rate of pesticides. Professor Yuan Huizhu of the Institute of Plant Protection of the Chinese Academy of Agricultural Sciences summed up in his article The Role of the Popularization and Application of Agricultural Drones on Improving the Utilization Rate of Pesticides in China: [5] “Compared with conventional knapsack large-capacity spraying on the ground, the pesticide utilization rate of agricultural drone’s low-altitude and low-capacity spraying technology in the prevention and control of crop diseases and insect pests such as rice, wheat and corn reached 49.1%, 57.1%, and 52.7%, respectively. Compared with the conventional knapsack large-capacity spraying on the ground, the use of agricultural drones can increase the utilization rate of pesticides by more than 10%. 1 billion hectares of operation is equivalent to reducing the waste of 1515 tons of pesticides.”

For the application of Cirsium arvense on the premise of achieving the control effect, compared with the traditional tractor, using drone to accurately weed 18 hectares can save 61 L of liquid, thus saving operating cost of 262.3 euros, or about 15 euros per hectare. Obvious economic effects have been achieved.

“If we are to achieve the 50% reduction in agrochemical use in Europe by 2030, our best chance is to use precision spraying / spreading and variable operation,” said Elemer, an engineer from Planta Drone.

IV. The tests of Agricultural drone

(I) Efficacy test of pesticide application

The effectiveness of pesticide application by agricultural drones has been tested in China for several years. The combination of industry, university, and research has played a positive role in promoting the development of agricultural drone industry technology. In 2021, tests using the DJI Agras T30 included the control of weeds in paddy fields, citrus red spiders, and fall armyworm in corn fields.

1. Test on the effect of controlling weeds in rice field

The purpose of this test was to comprehensively test the control effect of pesticide additives sprayed by the DJI Agras T30 on annual weeds in paddy fields. As a result, the appropriate agents and auxiliaries were selected, and the best parameters of pesticide application for agricultural drone were obtained. The test was conducted to explore the effect of spraying herbicide on barnyard grass and rice yield by the DJI Agras T30.

It was concluded that the control effect of the DJI Agras T30 is better than that of ground mechanical spraying methods. In addition, no obvious drug damage occurred during the experiment, indicating that the correct use of the two spraying methods can effectively control weeds in paddy fields. In addition, the DJI Agras T30 saves time, water and labor, and are recommended for weed control in paddy field.

2. Test on control of citrus red spider

Citrus red spiders are harmful to adult mites, young mites, and nymph mites, to absorb juice from leaves, shoots and pericarp, resulting in fallen fruits and leaves. The injured leaves are densely covered with gray-white needle-sized points, losing luster, and eventually fall off, seriously affecting the tree and yield potential.

In this experiment, the effect of spraying pesticides and auxiliaries on the control of citrus red spiders by agricultural drone was tested, and the appropriate application parameters, pesticides and auxiliaries of agricultural drone were selected.

The main results are as follows:

1. According to the theory of optimal biological particle size, the range of droplet size captured by different biological targets is different, and only in the range of optimal particle size, the number of droplets captured by the target is the largest and the control effect is best. For foliar reptile pests such as citrus red spiders, fog droplets with a particle size of 40~100 μm are suitable. For these parameters, the DJI Agras T30 is suitable for citrus orchard to control red spiders.

2. Among the two kinds of insecticides, the quick control effect of SC was better, and the lasting effect was general. 5% Avi EC + 20% ethoxazole SC had ideal quick-effect and persistent effect on the citrus red spider, and the control effects were 94.36% (1D), 98.37% (3D) and 85.74% (10D), respectively.

3. Adding orange agent can improve the control effect and spraying uniformity of the citrus red spider, in which 40% acarazole SC added orange additive, the control effect increased by 11.68% (3D) and 4.44% (10 d).

3. Control Test of Spodoptera litura in Corn Field

Spodoptera litura, commonly known as the tobacco cutworm, is a leading target for pest prevention. The selection of application instruments, pesticides, auxiliaries, and application methods are the key technologies for the prevention and control of Spodoptera litura. The application of the DJI Agras T30 was compared with the knapsack electric sprayer on the ground, so as to provide a basis for the field control of Spodoptera litura. Spodoptera litura is mainly harmful to corn heart leaves, so the amount of pesticide deposition in heart leaves is the key to the control of Spodoptera litura.

The droplet analysis collected from the filter paper placed on the leaves of the corn ears showed that the deposit amount of the solution applied with the DJI Agras T30 was only 4.6% of that of the knapsack sprayer, but the control effect could reach the same level as that of the knapsack spray.

(II) Drift test

1. Traditional aircraft drift model

People have long recognized that aircraft spraying will bring the problem of pesticide drift, so there has been related research on the drift of traditional aircraft for a long time. The AgDRIFT model of the United States is used to officially regulate agricultural aviation spray-related matters. Users can input nozzles, pesticide fluids, aircraft types, weather factors, etc., and predict the possible drift by calling the internal database. In this model, aircraft wake, wingtip swirl, helicopter rotor downswirl, and air disturbance around the fuselage are included in the influence factors on fog droplets.

Andrew Hewitt, a professor at Queensland University in Australia, introduced GIS into the aviation drift model to optimize the spraying strategy through the measurement of real-time wind speed to reduce pesticide drift loss in non-target areas.

These studies on the traditional aircraft drift model have laid a theoretical foundation for the drift test of agricultural drone.

2. Wind tunnel test

The deposit of fog droplets is affected by many factors. For the drone spray system, the spray droplet parameters, operation parameters, equipment structure types, and environmental factors will affect the droplet deposition effect. During the operation of the rotor drone, the downwash flow produced by the rotors will also affect the distribution deposit of the liquid.

The wind tunnel test makes it possible to quantify the influence of spray parameters on droplet deposition. By comprehensively considering the influence of many factors, such as nozzle type, wind speed, height, and reagent type the prediction model of droplet deposit and drift can be established to guide the actual spray operation. Although the wind tunnel test has obvious advantages in the analysis of deposit-influencing factors, the wind tunnel laboratory is expensive and requires a high standard of conditions and it is difficult to consider the flight parameters and the influence of downwash flow field during drone flight operation.

3. Field test

The advantage of field experiments is that the results of droplet drift and deposit can be observed and analyzed more directly on the basis of drift simulation experiment and wind tunnel test. The disadvantage of field experiments is that the process and results are not reproducible due to the growth and weather conditions of the crops themselves.

1) Pesticide droplet drift test

The purpose of the pesticide droplet drift test is to study the effects of agricultural drone flight height, liquid application volume, external wind speed, and nozzle type on the droplet deposit and drift characteristics of different pesticides.

The main purpose of the pesticide droplet drift test is to confirm the degree of droplet drift under different conditions through the actual flight of agricultural drone, and then provide some guidelines for users in actual operation. For example, the operation should pay attention to the weather, temperature, wind direction, wind speed, etc., and be based on the use of different agents, auxiliaries, and set up the corresponding isolation zone.

Taking the pesticide droplet drift test conducted by Corteva and China Agricultural University in 2021 as an example:

The length and width of the spray operation area was 20m×20m. The pattern of field deposit test sample is as follows:

Same as spray amplitude test;

The length of each row is a 20m droplet collection belt, a total of 2 rows, 0.5 m from the ground;

The length and width of the drift test area is 20×50 m;

Use petri dishes to receive droplets drifting from the ground;

Place petri dishes and potted soybean seedlings at a distance of 1, 3, 5, 10, 15, 20, 30 and 50 m downwind, 6 dishes (15 cm petri) on metal plates to maintain the same height, with a total of 48 petri dishes in each group;

The air droplet collection device is arranged at 20 m downwind to collect droplets drifting vertically in the air;

The collector adopts polyethylene hose, which is 1, 2, 3, 4, 5 meters from the ground.

The field weather station was used to obtain the information of environmental wind speed, wind direction, temperature and humidity, and record the information of each processing time, temperature, humidity, wind size and wind direction during the whole process of the experiment.

Pesticide drift test is now considered by countries all over the world, and drone companies, chemical companies, and agricultural universities are doing corresponding research. Germany, China, Hungary, Australia, Japan, Ukraine and other countries have also conducted similar tests, hoping to provide a basis for the rules for the use of agricultural drones.

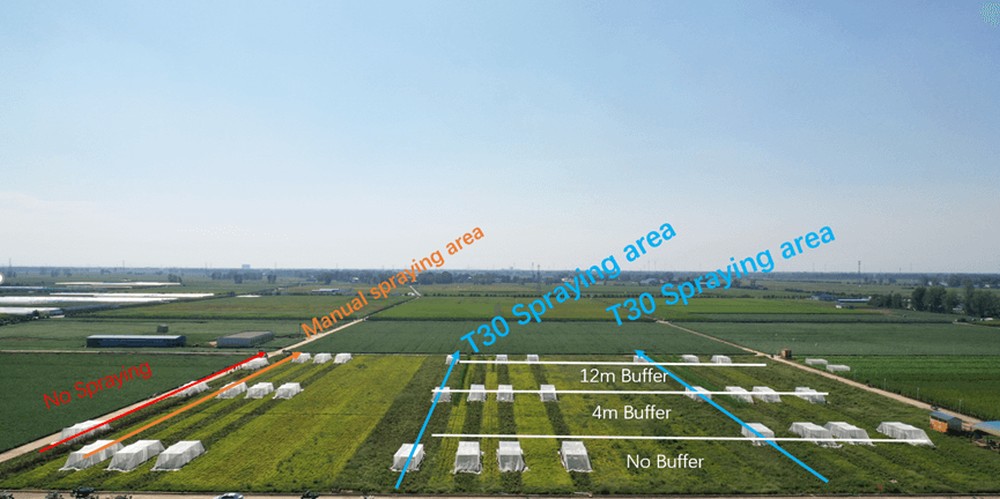

2) Environmental impact assessment test

In 2021, the Institute of Plant Protection of Chinese Academy of Agricultural Sciences carried out the safety assessment test of spray drift of agricultural drones on honeybees. The purpose of the test was to:

Determine the deposit and distribution of droplets in the application area and drift area;

Compare the effects of pesticide droplet drift on honeybees with different application methods;

Clarify the control effect of different width of isolation zone on the drift of pesticide application in agricultural drones.

The specific preparation and route of spraying equipment were as follows:

Use the DJI Agras T30 for spraying and Mavic 2 Pro for aerial recording;

T30 spraying parameters of: speed 6 m/s, flight altitude 6 m, spray amplitude 8 m;

Fly east to west along the spraying zone, take off from the easternmost side of the field, spray to the westernmost end with a spray amplitude of 8 meters, and then spray from the westernmost zone of 8-16 meters to the east and land.

At the same time, the knapsack sprayer was used for manual spraying at a spraying height of about 0.7-0.8 m from the ground, a flower height of about 0.3-0.4 m, and a spraying range of 8 m. One person advanced in the middle of the spraying zone and sprayed on both sides.

No spraying zone was set on the westernmost side as a reference for comparison.

After spraying, the activity of honeybees was continuously observed for 16 days, and the activity of honeybees in different application areas and drift areas was recorded.

The results of the experiment, which will last for three years, will be used to recommend the best practices for agricultural drone spraying.

V. Exploration of best practices

The best practice of agricultural drones is a whole-process and full-cycle practical exploration from “person, drones, technologies, pesticide” in all directions. In this process, it involves crew training, the upgrading of safety and reliability of agricultural drone products, the upgrading of drone technology, the coordinated upgrading of agricultural planting technology, as well as the improvement and use standards of pesticides used.

(I) Crew Training

Improper use of agricultural drones may cause environmental soil pollution, air pollution, water pollution, and other problems. These problems are often ignored by operators but can be completely avoided as long as the operation is standardized. For example, operators should not work in an environment with a wind speed of more than 12 mph and do not dump the water from cleaning the spray tanks into natural water sources,. At this time, the requirements for operators are no longer limited to flying agricultural drones, but are trained to become professional agricultural drone operators.

Professional agricultural drone operators refer to people who have both drone operation skills and professional plant protection knowledge. Agricultural drone operators receive systematic training from manufacturers, take up certified posts, are very familiar with agricultural and aviation-related regulations and standards, and master the knowledge of scientific and safe pesticide use. They can carry out dispensing and operation according to the scientific and safe drug use operation plan so as to avoid the impact of drift on surrounding non-target crops, pollinating insects, and the ecological environment.

With regard to the official requirements for agricultural drone operators, the most typical practice comes from the Philippines. On March 18, 2021, the Technical Education Skills Development Authority (TESDA) issued the II Agricultural Drone Operation Capability Standard (CS), announcing the formal inclusion of the DJI UTC course in the national skills training program, which means that the DJI course has become the first officially certified agricultural drone training course in the Philippines.

(II) Development of new technology

1. Nozzle technology

Researchers in many countries have also spent years studying various spray nozzle types, including general, electrostatic, anti-drift, and gradually precision-variable nozzles. The centrifugal atomizer controlled by the motor has the characteristics of narrow droplet size spectrum distribution and wide atomization range. Compared with the effect of a hydraulic atomization nozzle, it has obvious advantages that has allowed it to enter the commercial stage. MEMS system technology will further miniaturize the control and actuator, and a fine-adjustment spray droplet spectrum for anti-drift and precision variable application has become a new research trend. In addition to traditional pressure nozzles, agricultural drones have also begun use centrifugal nozzles. The characteristics of centrifugal nozzles are: (1) droplets can be controlled, and droplet diameter can be effectively controlled by adjusting rotation speed; (2) a large flow channel structure will not cause blockage, so it is very suitable for spraying soluble powder and suspended agents.

2. RTK navigation pesticide application technology

Agricultural drones are equipped with a real-time kinematic (RTK) unit to achieve accurate positioning at the centimeter level. Before the pesticide application operation, the operators accurately measure and determine the boundary points of the pesticide application operation area by means of a handheld remote control, drone measuring point, or aerial survey, and form a pesticide application area map. According to the application area map, the route map of the application operation is planned, and the drone will automatically apply the pesticide accurately in accordance with the prescribed route to effectively avoid repeat and leakage spraying.

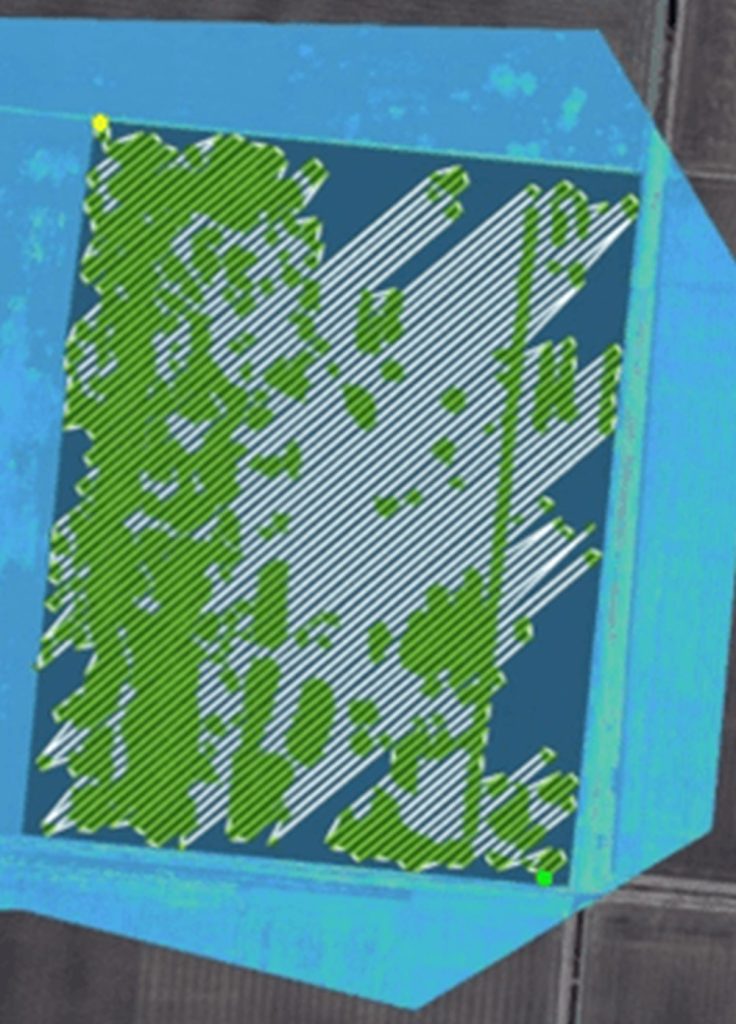

3. AI precision variable spraying

Agricultural drones use AI prescription maps to accurately identify farmland boundaries, crop density, and growth trends, as well as effectively reduce the use of pesticides and fertilizers through precise variable control, making it more environmentally friendly. The distribution and growth of crops in farmland are often different. Although full-coverage spraying can achieve large-scale and efficient operation, it will undoubtedly lead to waste of pesticides and environmental pollution.

AI precision variable operation can help users to make accurate judgment first, and then carry out specific operations to reduce the waste of pesticides and environmental pollution. This technology has been widely used in different crops. Below are several uses.

1) Precision spraying weeding

Multi-spectral monitoring was used to monitor the fields before and after sowing, NDVI vegetation index was used to separate the occurrence location of weeds, and the prescription map of accurate spraying was generated and sprayed to agricultural drone to achieve accurate weeding.

The use of agricultural drones for precision weeding to solve a series of problems such as the high cost of herbicide use and ecological pollution caused by pesticide abuse will see increasing use all over the world. While reducing drugs and increasing efficiency, we will promote the green and sustainable development of global agricultural ecology.

2)Accurate spraying of the oil palm tree heart

Most of the diseases and insect pests of oil palm occur in the heart of the tree. When the young oil palm is invaded by pests such as coconut rhinoceros beetle (Oryctes rhinoceros), it will cause leaf damage, petiole holes, and spear fractures and breaks, resulting in tree deformation and dryness, and finally lead to the premature death of young oil palm trees.

DJI agricultural drones provide a customized service, Oil Palm mode, for the management of pests. Using the T16 oil palm special nozzle layout system and DJI Terra fruit tree pattern AI recognition, the tree heart can be accurately judged and sprayed at a fixed point, which can achieve the best pest control effect, save water, and use medicine more efficiently.

(III) Pesticides and flight control additives

Pesticide formulation is a very important factor affecting the actual use of pesticides, which can improve the atomization process of droplets, reduce the loss of droplets, and increase the retention of pesticide droplets on the surface of target crops. So far, commercial pesticide preparations for drone application are still in the stage of research and development, and the preparations suitable for low-altitude and low-dose pesticide spraying of drone will improve the uniformity of pesticide distribution and reduce the potential of droplet drift.

The development and promotion of special agents and auxiliaries that are suitable for agricultural drones has become the key to their low-capacity pesticide application potential. Large chemical companies, such as Corteva, Syngenta, and Bayer are actively developing flight prevention auxiliaries that match agricultural drone spraying. Considering the characteristics of drone plant protection operation in chemical formulation design and processing, there is a high risk of droplet drift in drone low-capacity spraying, so it is necessary to study pesticide preparations with strong sedimentation, volatility resistance, and drift resistance.

(IV) Establishment of technical standards

For the safe operation of agricultural drones, it is necessary to establish industry standards and norms.

The evaluation of environmental safety is the main and key content of the safe use of agricultural drones, environmental protection, and government management. The use standard of agricultural drones lags far behind the research and development of products. It is necessary to develop technical standards that can provide reasonable pesticide application parameters for drone operations under different weather and ground conditions. It is necessary to speed up the research and formulation of standards and norms for aviation plant protection operation quality, control effect assessment and environmental risk assessment. To promote the high-quality, high-efficiency, safe, controllable, and healthy development of the agricultural drone industry.

With the gradual popularization of agricultural drones in the world, the formulation of agricultural drone industry standards and norms has become a key factor to promote the development of the industry. In the aspect of international standards work, DJI belongs to the Agricultural and Forestry Tractor and Machinery Standardization Technical Committee (ISO/TC23) of the International Organization for Standardization (ISO), specializing in the standard research of tractors, plant protection equipment, agricultural electronics and other fields, under which the working Group on drone spraying system (WG25) has been established, and is currently deeply involved in the formulation of international standards for agricultural drone ISO-23117.

(V) Complete legal compliance before the start of the operating season

As mentioned earlier, agricultural drones are managed by a number of management departments. The use of agricultural drones is affected by crop growth cycles. We generally refer to the cycle of sowing and spraying of agricultural drones as the agricultural operation season. In order to ensure that users can comply with the use of agricultural drones at the beginning of the operating season, the compliance work should be completed before the start of the operating season. According to the current law, some compliance content cannot be easily completed by users, and manufacturers can assist users in compliance in advance.

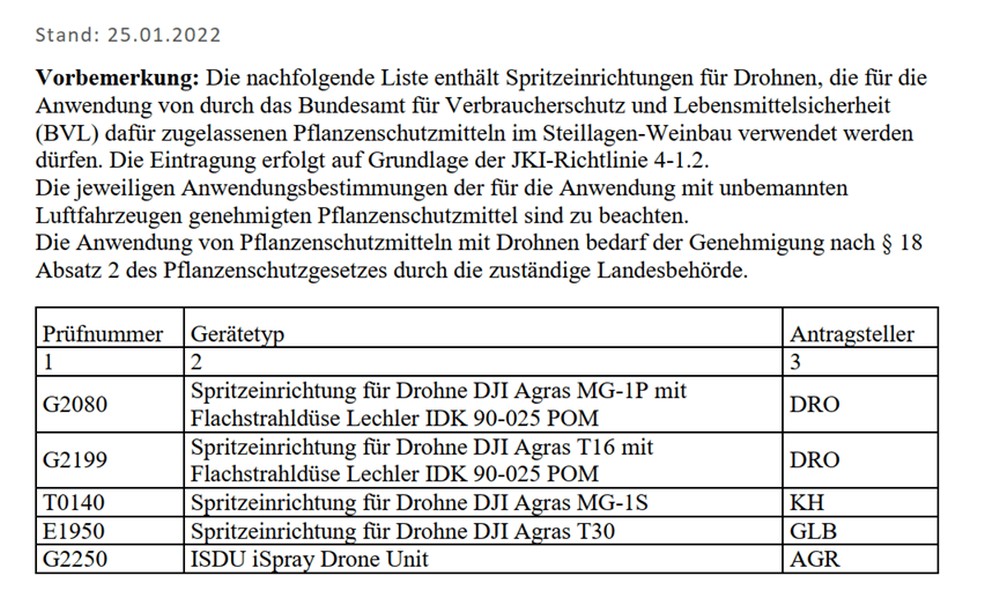

1. JKI Certification in Germany

As a well-known agricultural machinery certification organization, German JKI has a reputation for a high standard of professional nozzle testing. In Germany, agricultural drones must be certified by JKI before spraying pesticides on special plots. For example, in 2021-2022, JKI tested and certified the DJI T30 for mountain vineyard operations and completed this approval before the start of the operating season.

2. SFOC Compliance of Transport Canada

Transport Canada requires the operation of drones above 25 kg, operators are required to apply for SFOC, and Transport Canada is approved by SORA and standard scenarios. The content required in SORA includes the safety design of drones. As a terminal agricultural user, it is difficult to provide the safety design and reliability description of drone.

DJI applies directly to Transport Canada to replace T30 users to complete the safety design description and product reliability test report stipulated in the regulations. At present, T30 has been approved by Transport of Canada, and local farmers only need to state the time and place of their upcoming work when applying for SFOC, which greatly saves the compliance cost of users.

As a drone below 25 kg, the T10 must comply with Canadian Standard 922. In order to facilitate the use of users, DJI has also made the compliance of Standard 922, users can use it directly.

3. SORA Compliance of FOCA

In Switzerland, in order for agricultural users to pass the review quickly, agricultural drones are reviewed in advance by the Committee on Agriculture, and then approved by FOCA. Manufacturers or distributors can assist users in preparing corresponding product description materials in advance during the compliance process in order to pass the review quickly.

VI. Conclusion

As stated by the International Food and Agriculture Organization in its objectives:

Our goal is to achieve food security for all and make sure that people have regular access to enough high-quality food to lead active, healthy lives.

Agricultural drones provide modern scientific and technological tools for this goal, and create new jobs, new social needs, and social values in the process. Today, agricultural drones comprehensively cover major food crops around the world, including rice, wheat, corn, potatoes, and soybeans. They also serve major cash crops around the world, such as tea, citrus, apple, cherry, cotton, and sugar cane, to name a few.

With the digital, accurate, and intelligent management of grape, olive, cotton, and other cash crops, an agricultural drone system can provide practitioners with a more convenient and efficient management scheme, thereby reducing operating costs, increasing production, quality, and income. The application of agricultural drones will also consider more environmentally friendly and sustainable development in the future to make more contributions to a greener earth, make agriculture easier, and improve lives.

We embrace farmers and are determined to be of service generate their income. Through better intelligent equipment and solutions, we can effectively solve the problems in farmers’ production to help realize their dream of increasing income and make their work more valuable.

We pledge to protect the planet and continue to reduce waste and loss in agricultural production by creating better tools and programs. In doing so, we aim to enable more practitioners to carry out agricultural production in a more environmentally friendly way exist with the land in harmony.

We uphold a win-win cooperation and carry out industry-university-research cooperation with universities, chemical companies, research centers, and other institutions. We will jointly build an ecological circle with talent training, product upgrading, chemical optimization, and technological upgrading as the core, and jointly promote the development and progress of global agricultural science and technology.

We believe that with the continuous exploration of best practices, pest management, and pesticide use will be more reasonable and have less impact on the environment, the policy environment of agricultural drones will be gradually relaxed, and the space for the development of agricultural drones will broaden.

We would like to offer our sincere appreciation to all who worked hard for agriculture and contributed to environmental protection.

We would also like to thank every DJI colleague who worked on this report, DJI distributors and partners for their support in producing its content, and all those who provided media resources.

Finally, we must extend our deepest gratitude for the flora and fauna that provided the data from which future generations will benefit beyond measure.

[1] The agricultural chemical for unmanned aircraft, see https://mujin-heri.jp/index2.html

[2] Beratungsgesellschaft für integrierte Problemlösungen,see http://www.bipro.de/

[4] Special Investigation Report on the Safety of Agricultural Aircraft Operations. Special Investigation Report NTSB/SIR-14/01. United States National Transportation Safety Board, 2014

[5] Yuan Huizhu; Guo Yongwang; Xue Xinyu; Yan Xiaojing; Chen Chang; Kong Xiao; Wang Ming; Zhou Yang: “the role of the popularization and application of plant protection drones in improving the utilization rate of pesticides in China”, Agricultural Engineering Technology, no. 09, 2018